Fabrication and Machining Facility

Our fabrication and machining facility is well equipped with

machining and fabrication equipment and with highly skilled team

to provide the fabrication and machining services to our clients

and as well as to fulfill the requirement of the valve shop.

The Fabrication shop is equipped with conventional welding

machines. Experienced craftsman and welders carry out a variety

of arc welding activities, hard surfacing (Satellite 6 and Satellite 12)

as well as overlay welding (SS 410 and Inconel). Excellent quality

TIG welding on stainless as well as exotic materials likes Hastelloy

and Inconel (Nickel based on alloys).

Products Handled:

➢ General fabrication jobs.

➢ Gas Turbine components refurbishment

➢ Overlay welding of valve gates and stems

➢ Temperature resistant coating on valve stems.

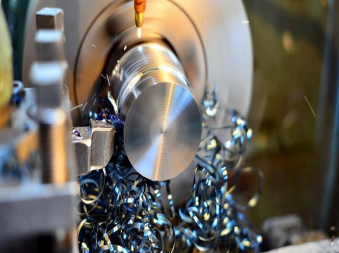

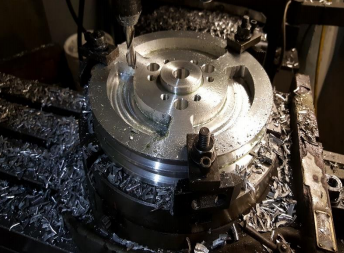

The Machine shop is equipment with conventional lathes, milling

machine, drilling machines and shaping machines. A fine boring

machine helps in finishing the bores of bearings and other critical

components to fine finish and tolerances. Skilled machinist carry

out precision machining activities on the machines to produce

components to very close tolerances.

Product Handled:

➢ General machining tasks.

➢ Machining of overplayed gates and stems

➢ Fabrication of valve stems for pipeline valves.